Last Updated: June 2023 (Cement Industry in India)

Table of Contents

Cement Industry in India

This article deals with the ‘Cement Industry in India.’ This is part of our series on ‘Geography’, which is an important pillar of the GS-1 syllabus. For more articles, you can click here.

Introduction

Raw Materials Required

Raw Materials required in the Cement industry are

- Limestone: 60-65%

- Silica: 20-25%

- Alumina: 5-12%

- Slag from Steel plant

- Slag from Fertiliser plant

- Sea Shells

Location Factors of the Cement Industry

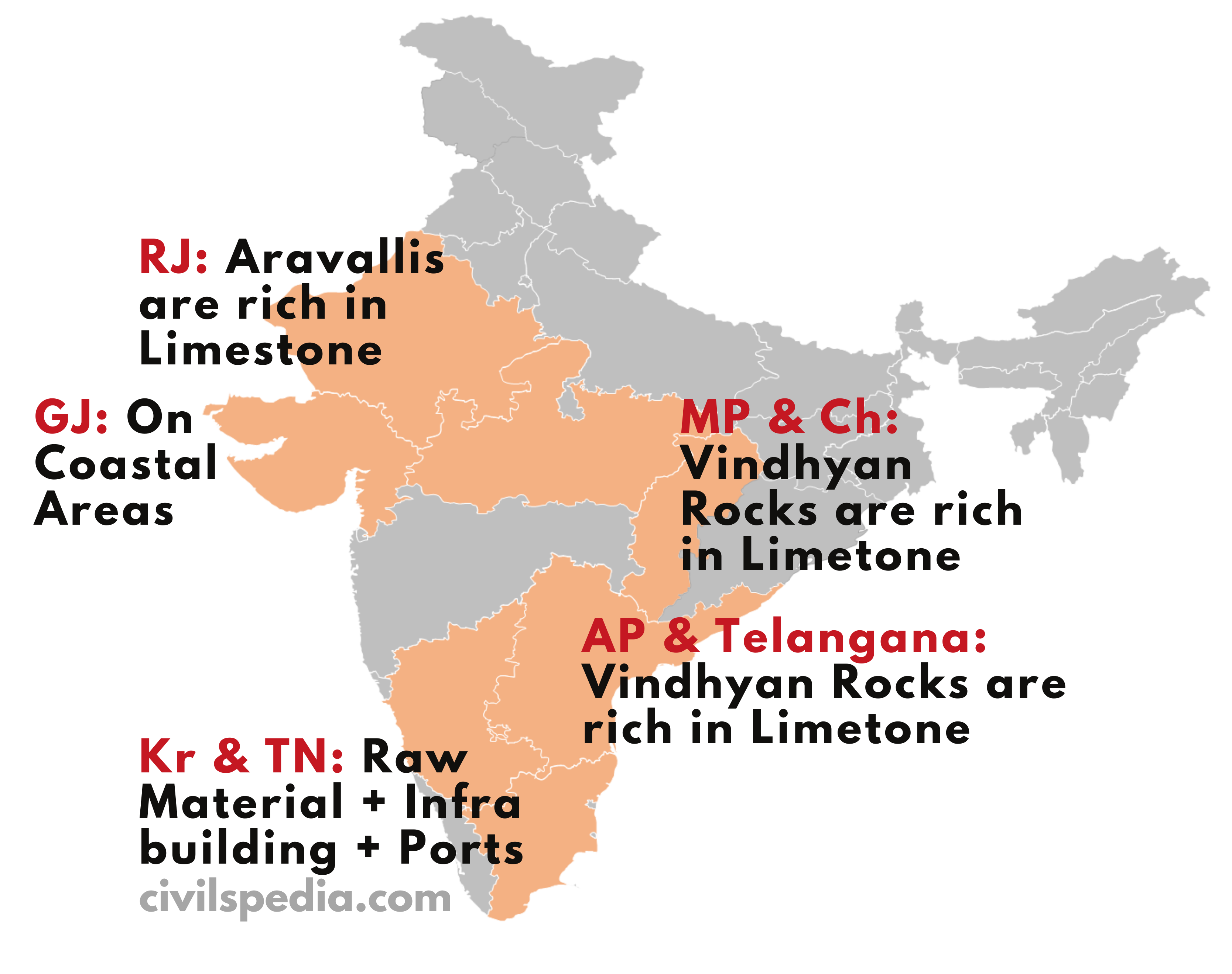

Availability of Raw Materials

- Limestone, clay, and gypsum are used in huge quantities in cement manufacturing. As a result, the cement industry is situated close to the raw resources. That’s why cement plants such as Ultratech Cement and Ambuja Cement are situated in Rajasthan (rich in limestone).

Infrastructure and Transportation

- The cement thus produced needs to be transported to the market. As cement is a heavy and bulky material, a well-developed network of roads, railways or ports (for exports) is required.

Power Availability

- Cement manufacturing is an energy-intensive industry. Hence, the cement industry is located in regions with an adequate and cheap energy supply like coal, hydroelectricity, or renewable energy.

Water Availability

- An ample water supply is required to manufacture cement for processes such as cooling. Hence, cement plants are situated near water sources, like rivers or lakes.

Government Policies

- Government policies and regulations can also influence the location of cement industries. Environmental regulations, tax benefits and subsidies can encourage or discourage the establishment of cement plants in that region.

Environmental Factors

- Air Pollution Regulations can affect the location of the cement industry. Since Cement is a polluting industry, it is not situated in states with strict air pollution requirements.

Geological Considerations

- Geological factors, especially the quality and composition of limestone deposits, can influence the location decisions of cement plants.

Major Cement Producers

Major industrial houses in the Cement Industry in India include

- UltraTech Cement

- ACC Limited (Headquartered in Mumbai)

- Ambuja Cement (Mainly Gujarat based)

- Shree Cement (Beawar (Rajasthan) based)

- Ramco Cement (Chennai based)

- Dalmia Bharat Cement (Tamil Nadu based)

- JK Cement

New Opportunities for the Cement Industries

- The Ministry of Transport has decided to build concrete cement roads instead of traditional bitumen roads as cement roads are cost-effective & require less maintenance.

- Rapid urbanization and infrastructure development have increased the demand for Cement in India.

- Government programs like “Housing for All” have increased the cement demand in India.

- India is exporting cement to its neighbouring countries like Nepal, Bangladesh, Sri Lanka, and Bhutan, as well as to markets in the Middle East, Africa, and Southeast Asia.