Semi-Conductor Industry (in India and World)

This article deals with the ‘Semi-Conductor Industry (in India and World).’ This is part of our series on ‘Geography’, which is an important pillar of the GS-1 syllabus. For more articles, you can click here.

Introduction

A semi-conductor is a substance characterized by its capacity to carry a small electrical current. The essential criterion for a semi-conductor is that it should neither be an excellent conductor of electricity nor a poor conductor; instead, it falls in between these extremes.

Semiconductors function by virtue of an electron imbalance. This imbalance of electrons generates positive charges (WHERE THERE ARE EXCESS PROTONS) and negative charges (WHERE THERE ARE EXCESS ELECTRONS) at two ends of surfaces of the semi-conductor material.

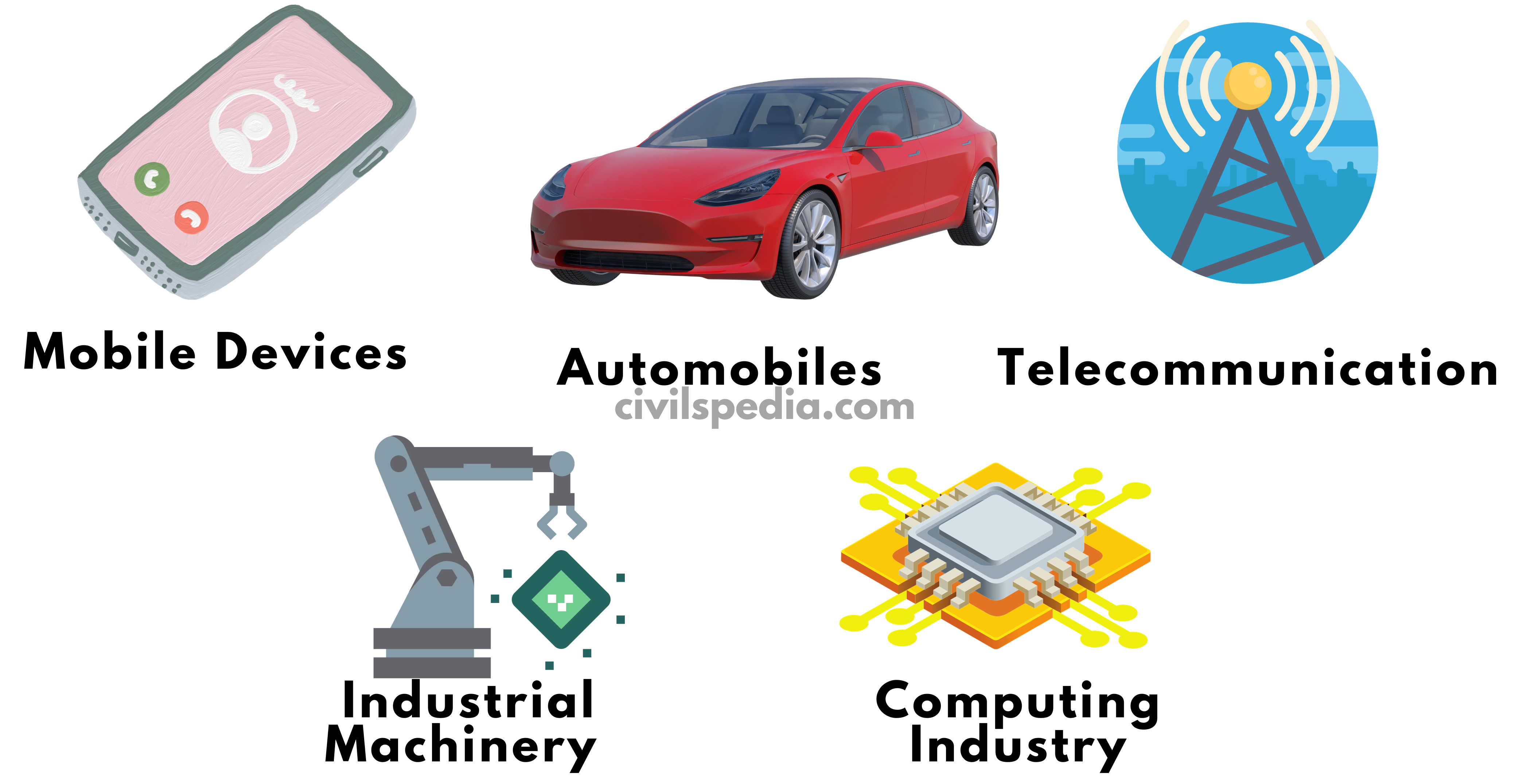

Due to this helpful characteristic, it is used in the following industries

Location Factors for Semi-Conductor Industry

Research and Development Centers

- Proximity to leading research and development institutions and universities focusing on technology and engineering is crucial.

Skilled Workforce

- The availability of a highly skilled workforce specializing in electrical engineering, materials science, and related fields is essential.

Infrastructure and Connectivity

- Robust infrastructure, including reliable power supply, advanced production facilities, etc., is a vital factor in determining the location of the Semiconductor industry.

Access to Capital

- The availability of large capital is essential as a semiconductor requires significant investments in research, development, and production facilities.

Government Support and Incentives

- Supportive government policies, tax incentives, and grants can attract semiconductor companies to a specific location.

Intellectual Property Protection

- Strong legal frameworks and intellectual property protection contribute to a conducive business environment for semiconductor companies.

Cluster Effect

- An established semiconductor industry cluster can attract more companies to a specific location. Clusters promote collaboration, knowledge exchange, and the development of specialized supply chains.

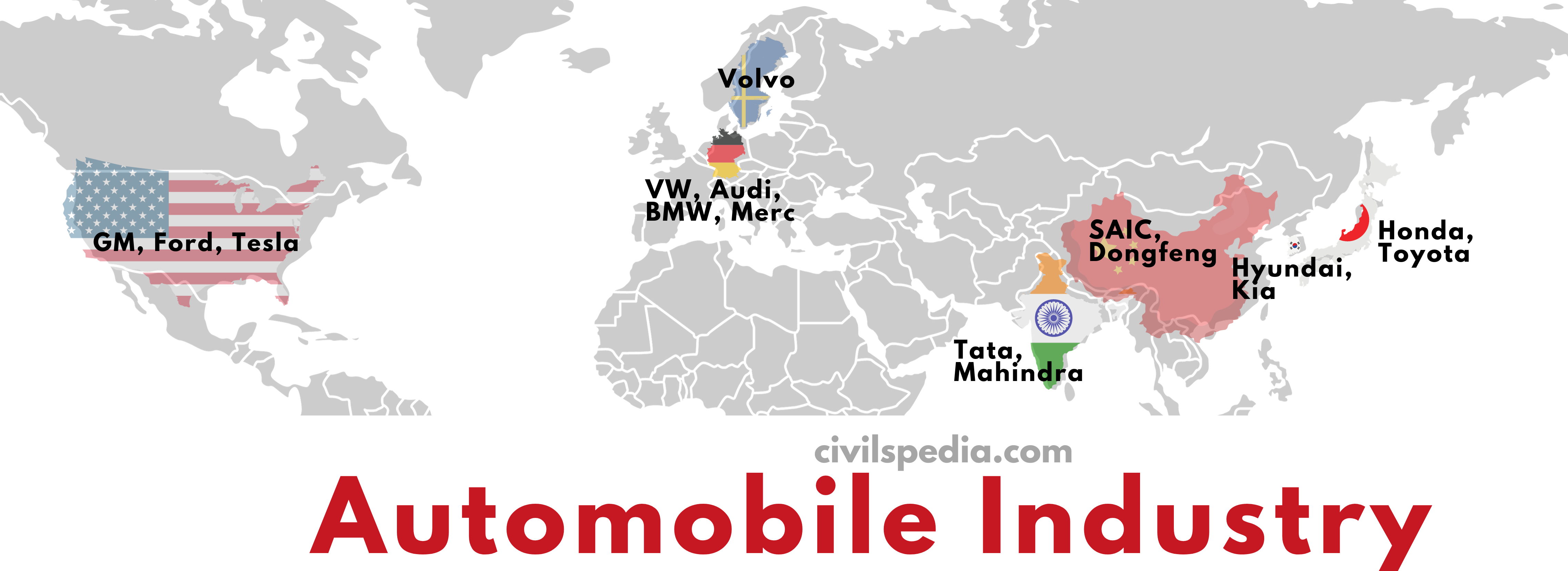

Global Semi-Conductor Industry

Taiwan

- Taiwan, specifically Hsinchu Science Park, is the largest semi-conductor producer, producing almost 60% of the global semi-conductors. Taiwan Semi-conductor Manufacturing Corporation (TSMC) is the largest producer of semi-conductors in the world.

- The island nation benefits from a robust industrial ecosystem, government support, and proximity to major Asian markets.

- Additionally, the Taiwanese government has actively supported the semiconductor industry through policies and investments.

The USA

- The USA is the second most significant producer.

- The US is home to Silicon Valley in California, a global technology and semi-conductor innovation hub.

- It benefits from a well-developed infrastructure, large market, skilled workforce, and proximity to research institutions.

South Korea

- With companies like Samsung, South Korea is a significant player in semiconductor production.

China

- China has been aggressively investing in its semiconductor industry.

- Government policies, access to a large consumer market, and technological advancements contribute to China’s presence in the industry.

Japan

- With companies like Toshiba and Renesas, Japan has a long history in semiconductor manufacturing.

- A robust industrial base and a focus on high-tech manufacturing contribute to Japan’s position in the semiconductor industry.

Indian Semi-Conductor Industry

Historically, India has heavily depended on semi-conductor imports from Taiwan and Hong Kong to meet its growing demand for electronic goods.

The Indian Government has recognized the strategic importance of the semi-conductor industry and has taken steps to encourage its growth.

Why Should India Invest in the Semi-Conductor Industry?

- Save Forex and Earn Revenue: Investing in semi-conductor manufacturing in India will diminish reliance on imported semi-conductors for domestic companies and generate revenue through exports to global markets. This strategic move could position India as a key global hub for electronic goods, fostering job creation and attracting investments from top multinational firms.

- Meeting Escalating Demand: The surge in digitization, coupled with advancements in intelligent computing and the rise of artificial intelligence (AI), has led to an unprecedented demand for semi-conductors and chipsets.

- Self-Sufficiency (Atma Nirbhar): Establishing a semi-conductor industry in India would contribute to the nation’s self-sufficiency, addressing the challenges of supply chain disruptions witnessed during the COVID-19 pandemic.

- Multiplier Effect: Developing indigenous semi-conductor manufacturing capabilities will create a positive ripple effect on related industries.

Initiatives to promote Semi-Conductor Manufacturing in India

- Production Linked Incentive (PLI) Scheme for IT Hardware and Semi-Conductors: The Government is giving incentives on goods manufactured in India.

- Semicon India Program: The Government is providing financial support to companies who are investing in the development of the semi-conductor ecosystem, such as fabrication (fab), research, design and testing facilities.

- Design Linked-Incentive Scheme: The Government provides financial support of 50% of eligible expenditure on the design, subject to a ceiling of ₹15 crores per applicant.

- National Policy on Electronics, 2019: The policy aims to make India a global hub for designing and manufacturing Electronics Systems, including Chipsets.

- Foreign Direct Investment: 100% FDI in the semi-conductor industry is allowed via Automatic Route.

- Collaborations and Partnerships: The government is signing MoUs with various countries to invest in the Indian semi-conductor industry. For example, Israel has signed a MoU to invest 22,000 cr.

Challenges faced in manufacturing Semi Conductors

- Complex Value Chain: The semi-conductor value chain has three major components: Design, Fabrication, and Assembly and Testing. These processes are very expensive as they are highly dependent on R&D and Intellectual Property protection.

- Massive Investment: Semi-conductor manufacturing is a complex, capital and technology intensive process. Semi-conductor Fabrication facility requires many expensive devices. Estimates put the cost of building a new fabrication facility (fab) over one billion dollars.

- Lack of Skilled Workforce: Insufficient skilled labour poses a challenge for semi-conductor companies; India falls short of meeting this crucial requirement.

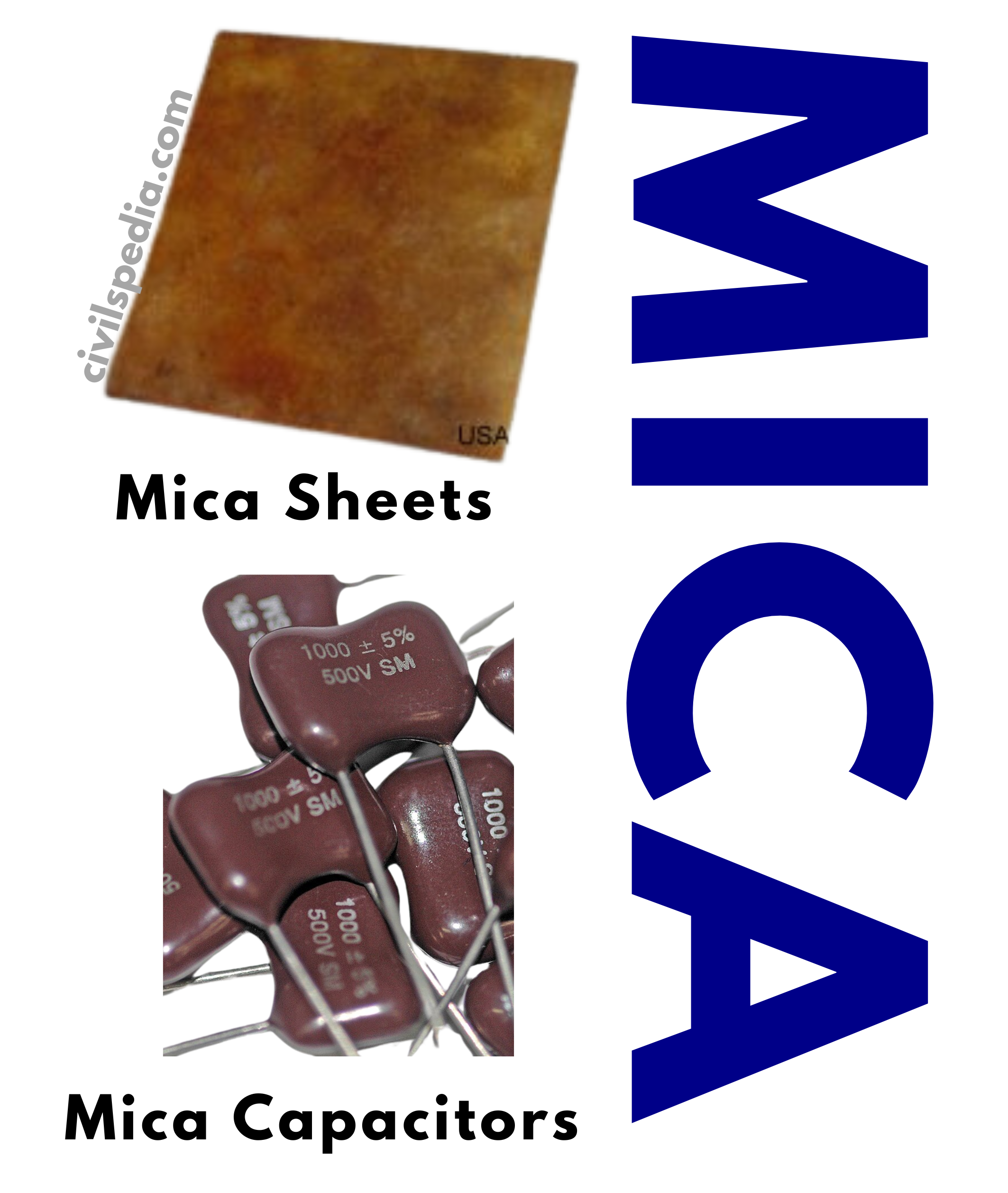

- Requirement of very specific Raw Materials: Apart from Silicon, numerous types of chemicals & gases are involved in semi-conductor fabrication that are not till now available in India.

- Lack of uninterrupted Power and Water Supply: Manufacturing a single semi-conductor chip requires thousands of gallons of pure water and an uninterrupted power supply.

- Global Competition: It is also difficult to compete with Taiwan and China, which, due to better cost-efficiency and first mover advantage, have become the favoured destinations for global chip manufacturers.