Table of Contents

Cotton and Textile Industry (in India and World)

This article deals with the ‘Cotton and Textile Industry (in India and World).’ This is part of our series on ‘Geography’, which is an important pillar of the GS-1 syllabus. For more articles, you can click here.

Location Factors of the Cotton & Textile Industry

Many factors have influenced the establishment of cotton and textile industries in India.

- Proximity to Raw Material: Unlike other industries where the weight or perishability of raw materials is a critical concern, cotton and textile industries benefit from the fact that cotton is relatively lightweight and non-perishable. Therefore, being in immediate proximity to the source of raw cotton is less important than in some other industries.

- Proximity to Market: Given the importance of market demand in dictating the type of cloth to be produced, a significant consideration is the proximity to the consumer markets. Being close to the market facilitates efficient distribution and reduces transportation costs.

- Water Availability: The textile industry involves processes like dyeing and bleaching that require substantial amounts of water. Consequently, the availability of water bodies such as rivers and lakes plays a role in industry location.

- Energy Availability: Cotton and textile production requires a considerable amount of energy, particularly in processes like spinning, weaving, and finishing.

- Labour Supply: Textile production involves intricate processes that require skilled workers, and a region with an ample labour pool can provide a competitive advantage.

- Capital and Finance: Access to financial resources can facilitate expansions, modernization, and technological advancements.

- Climate: Climate considerations are also relevant. Dry climates can lead to thread breakages during textile production. Historically, this led to the preference of coastal areas with higher humidity for textile industry setup. However, technological advancements, such as artificial humidifiers, have diminished the climate-related constraints on industry location.

At present, the trend is to locate industry at or close to markets, as the market decides what kind of cloth is to be produced.

Cotton Industry in India

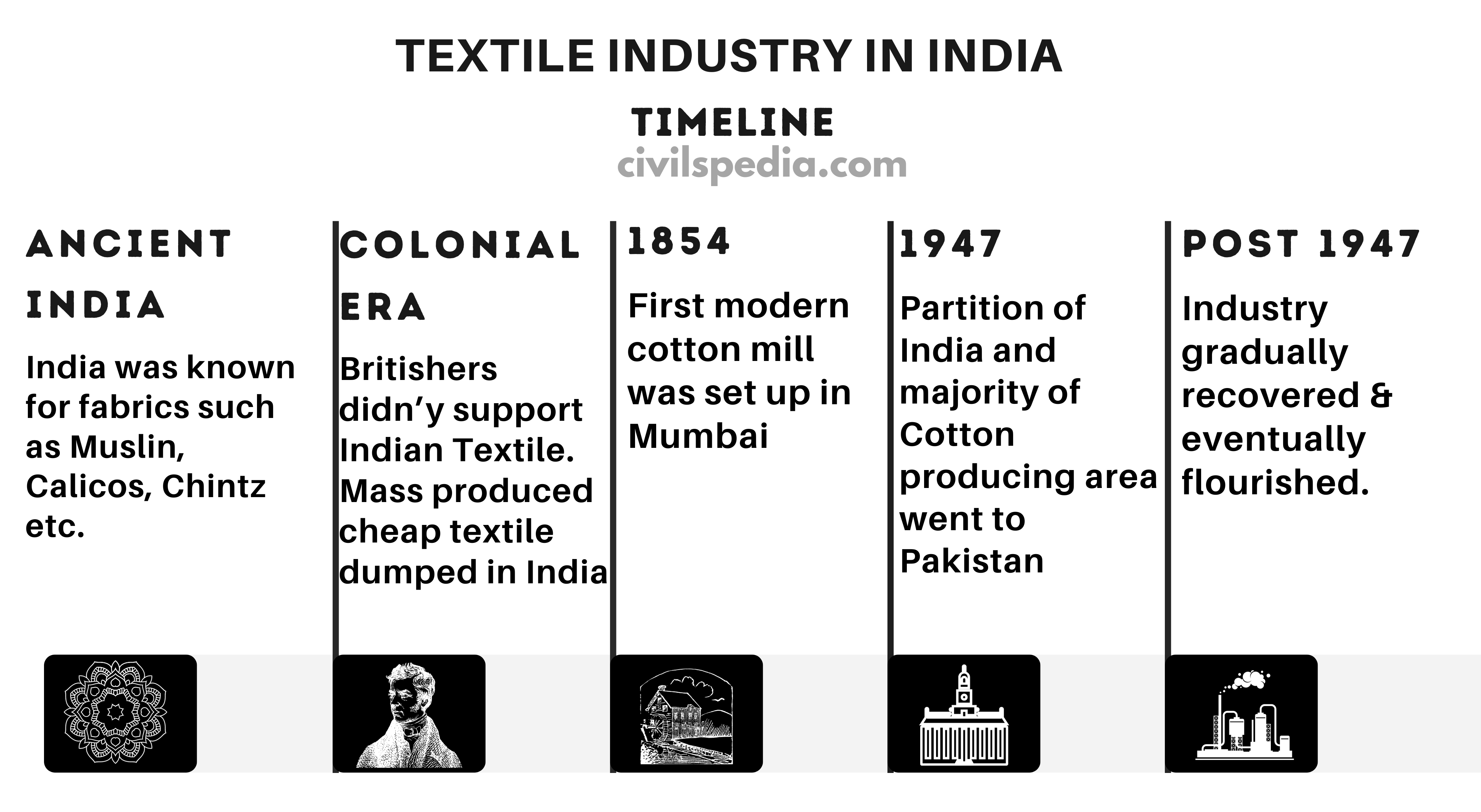

Cotton Industry in Ancient & Medieval India

- The cotton textile sector has been integral to India’s traditional industries. Across the globe, India held a renowned reputation for crafting muslin, an exceedingly delicate form of cotton fabric, along with calicos, chintz, and various other superior cotton textiles.

- The development of the textile industry in India stemmed from many factors.

- Firstly, the nation’s tropical climate made cotton the optimal fabric, providing a large market.

- Secondly, India has abundant raw materials due to the substantial cultivation of cotton.

- The country possessed an abundant reserve of skilled labour necessary for this industry.

During the Colonial Era

- Initially, the British didn’t foster the growth of the native cotton textile sector. They shipped raw cotton to their mills in Manchester and Liverpool, then imported the finished goods back to India. These products were more affordable due to mass production in British factories.

- In 1854, the first modern cotton mill was set up in Mumbai. The city had various advantages as a hub for cotton textile manufacturing:

- It was situated close to Gujarat and Maharashtra, key cotton-producing regions.

- Mumbai’s status as a financial centre provided access to the necessary capital for industrial initiation.

- Its urban nature attracted a substantial labour force, ensuring a readily available pool of affordable workers.

- The machinery required for cotton textile mills could be directly imported from England.

- Subsequently, Ahmedabad saw the establishment of two more mills, namely the Shahpur Mill and the Calico Mill.

- By 1947, the total number of mills in India rose to 423. However, this situation changed after the partition, leading to a significant downturn in the industry. This was because most of the prime cotton-producing areas were now in West Pakistan, leaving India with 409 mills and only 29% of the previous cotton-producing territory.

After Independence

- After Independence, this industry gradually recovered and eventually flourished.

- Production of cotton cloth has increased almost five times since Independence. Cotton textile has been facing tough competition from synthetic cloth.

Importance of Cotton and Textile Industry

India’s Cotton and Textile industries are vital to the nation’s economic landscape, owing to their multifaceted significance and widespread impact.

- Backward Linkage with the Agriculture Sector

- Employs 4.5 crore individuals

- Approximately 12% of the nation’s total exports are comprised of textiles and textile products.

- Rural Development: Cotton cultivation and subsequent processing through the textile value chain often occurs in rural areas. As a result, the growth of these industries contributes to rural development.

Location of Cotton and Textile Industry in India

The Cotton and Textile industry is located in almost every state where one or more locational factors have been favourable.

| South India | Coimbatore, Madurai, Tirunelveli and Bengaluru |

| Central India | Ahmedabad, Vadodara, Ujjain, Nagpur, Indore, Kolhapur and Solapur |

| UP | Kanpur, Agra and Hathras |

| West Bengal | Kolkata (due to port facilities) |

| Punjab | Ludhiana |

Important Points

- Among the major centres of this industry, Ahmedabad, Bhiwandi, Solapur, Kolhapur, Nagpur, Indore, and Ujjain stand out, which are strategically located in proximity to cotton-producing regions, optimizing their supply chains.

- The role of hydroelectricity in shaping the industry’s geography cannot be overlooked. Cotton textile mills began to sprout away from traditional cotton-producing areas due to the availability of hydroelectric power. This shift is particularly evident in Tamil Nadu.

- Labour costs can play a pivotal role in determining industry locations. Centres like Agra, Ujjain, Bharuch, Agra, Hathras, Coimbatore, & Tirunelveli capitalized on lower labour expenses, prompting the industry to be located away from primary cotton-producing areas.

Reasons: Why Cotton and Textile Industry is located in Mumbai?

Mumbai, known as the “Cottonopolis of India,” is the epicentre of the country’s thriving cotton and textile industry.

- Abundant Raw Material: Maharashtra, particularly the region around Mumbai, has black soil well-suited for cotton cultivation.

- Access to Premium Cotton: Being a busy port, Mumbai historically had access to international trade routes as a bustling port city, allowing the import of long-staple cotton from places like Egypt.

- Favourable Climate: Mumbai’s proximity to the sea results in a humid coastal climate conducive to textile manufacturing.

- Reliable Power Supply: The Tata hydroelectric grid in the nearby Western Ghats provides a consistent and reliable source of power.

- Availability of Soft Water: The Mithi River in Mumbai supplies soft water, which is ideal for dyeing and bleaching (important processes in the textile industry).

- Capital and Financial Infrastructure: During the American Civil War, Mumbai-based capitalists amassed substantial profits through the cotton trade. They later reinvested this wealth into the establishment of textile industries. Today, Mumbai is home to a well-developed banking and financial sector.

- Skilled and Affordable Labour: Mumbai and its surrounding regions provide a vast pool of labour, which is both skilled and cost-effective.

- Access to Expansive Markets: Mumbai’s strategic location places it at the heart of India, with access to the local and national markets.

Reasons: Why Cotton and Textile Industry is located in Gujarat?

- Abundant Raw Materials: Gujarat benefits from its proximity to cotton-producing districts in the state and neighbouring regions.

- Water Availability: Water is a crucial resource in textile manufacturing, particularly for dyeing, cleaning, and bleaching. Gujarat benefits from water sources such as the Sabarmati and Khari rivers.

- Proximity to Markets: Gujarat has a large domestic market for textiles, owing to its population and the presence of major industrial and commercial centres.

- Port Facilities: Gujarat’s coastline is dotted with major ports like Kandla, Mundra, and Pipavav. These ports offer excellent connectivity for the export of textile products.

- Government Support: The state government has been proactive in supporting the growth of the textile industry through favourable policies, incentives, and infrastructure development.

Reasons: Why Cotton and Textile Industry is located in Coimbatore (Tamil Nadu)?

- Abundant Raw Material Supply: Tamil Nadu has a consistent and substantial cotton supply. The region is known for cultivating a specific variety of cotton known as “Cambodia cotton,” which is highly sought after in the textile industry.

- Energy Resources: Coimbatore is home to the Pykara Hydel project, a significant source of hydroelectric power.

- Water Resources: Access to ample water resources is critical for various stages of textile production, including dyeing, cleaning, and bleaching—Coimbatore benefits from the Noyyal River.

- Market: Coimbatore has a massive demand due to its proximity to large consumer markets in the southern states, including Tamil Nadu, Kerala, Karnataka, and Andhra Pradesh.

Problem faced by Indian Cotton Textile Industry

- Fierce International Competition: The industry faces fierce competition from countries like Bangladesh, Vietnam, and Ethiopia, which enjoy Duty-Free Access or have signed Free Trade Agreements with major markets such as the EU and USA. This advantage puts Indian textiles at a disadvantage in terms of pricing and market access.

- Most Indian mills are small-scale operations, preventing them from achieving the economies of scale enjoyed by larger competitors.

- Mechanization vs Job Dilemma: The Indian industry is caught in a dilemma regarding mechanization. While mechanization can enhance productivity, it also threatens traditional jobs. Balancing technological advancement with employment opportunities is a critical challenge.

- Competition from synthetic textiles: The rise of synthetic textiles has further intensified the struggle for market share. Synthetic textiles often offer cost advantages and versatility.

- Cotton Farmers under stress: Indian Cotton Farmers face immense stress due to various factors, including the monopolization of seeds by a few major corporations and the introduction of genetically modified crops like BT Cotton.

Location of Cotton and Textile Industry in the World

The foundation of the cotton and textile industry lies in cotton cultivation. Cotton is primarily grown in regions with favourable climatic and soil conditions. Significant producers of cotton include

- United States: Cotton is grown in southern states like Texas and Mississippi

- India: Gujarat, Maharashtra, and Andhra Pradesh

- China: Northwest regions, particularly Xinjiang

- Pakistan: Sindh and Punjab provinces contribute significantly to Pakistan’s cotton production

- Brazil: Mato Grosso region

After cotton is harvested, it goes through a series of processing stages. Major cotton processing centres are concentrated in:

- United States: Southern states like North Carolina.

- India: Textile Mills are concentrated in Gujarat, Maharashtra, and Tamil Nadu

- China: Coastal regions like Shanghai, Zhejiang, and Jiangsu

- Pakistan: Karachi, Faisalabad, and Lahore

- Brazil: São Paulo and Santa Catarina

Analysis: Rise and Fall of Textile Industry in Manchester & Lancashire

The textile industry in Manchester and Lancashire has a rich history that witnessed remarkable growth during colonial times but declined significantly after World War II.

Rise during Colonial Times

- Favourable Climate: Manchester and Lancashire’s location was advantageous due to the moist Westerlies, providing high humidity levels and preventing threads from breaking during manufacturing.

- Abundant Raw Materials: Cheap cotton was available from its colonies, such as India and Egypt.

- Strategic Transportation: The proximity of Liverpool as a major port city facilitated the import of raw materials and the export of finished products.

- Quality Water Sources: Streams from the Pennine hills provided soft water, ideal for dyeing and bleaching.

- Abundant Energy: The availability of coal from Northern England and Wales served as a reliable source of energy.

- Expansive Market: The demand for textiles in Europe And the massive market in British colonies provided a market for the finished product.

Decline after World War II

The decline of the Textile industry after World War II can be attributed to the following factors.

- Loss of Colonies: Post-World War II, the loss of colonies meant that the dirt-cheap raw materials(cotton) from India and Egypt were no longer readily available.

- Competition from Other Nations: Emerging players like Japan entered the global textile market with cheaper production methods.

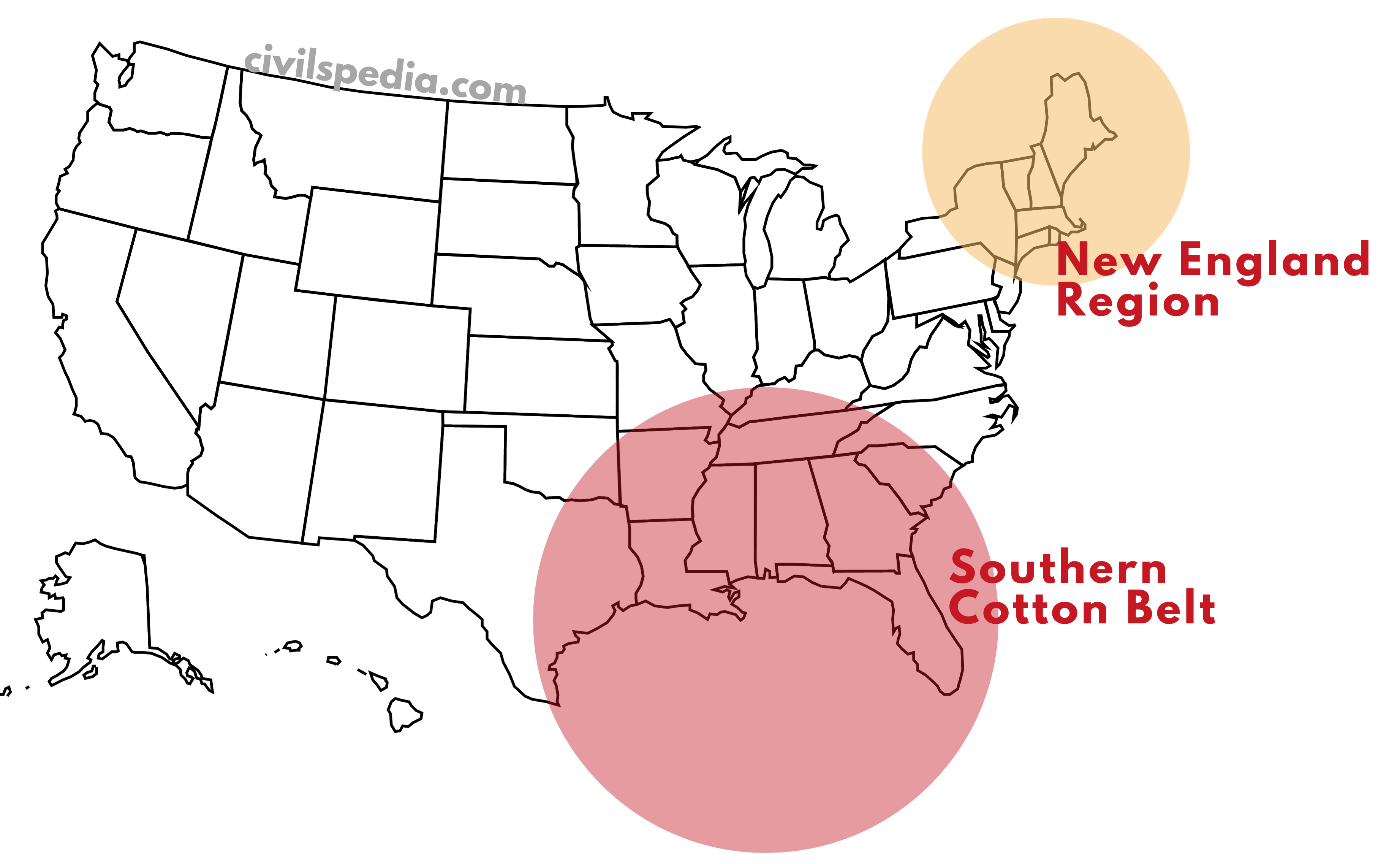

Reason: Cotton Industry in the USA

In the USA, there are two important regions of the cotton and textile industry, which can be attributed to several geographical factors.

New England Region

- It is located in the northeast corner of the US and emerged as a hub for cotton-related activities.

- Major factors of the concentration of cotton and textile industry include

- Its proximity to major urban centres like Boston and New York

- Easy access to ports for exporting cotton

- The region attracted immigrant workers, adding to the labour force and diversity of skills.

- The availability of coal from the Appalachian region ensured a stable energy supply, powering the cotton mills.

Cotton Belt in the South

- The Cotton Belt, stretching across states such as North Carolina, South Carolina, Georgia, Alabama, Mississippi, and parts of Texas and California, constitutes the heartland of cotton cultivation in the USA. This region boasts vast expanses of fertile land, forming large cotton-growing areas.

- Transformation from Slave Labour to Mechanization: Historically, the cotton industry in the South relied heavily on slave labour. However, over time, technological advancements led to the mechanization of cotton production. Highly efficient machines revolutionized the industry, making it less reliant on human labour.

- Hydroelectric Power: Major rivers in the cotton-producing regions have been harnessed for hydroelectric power generation.

Reason: Cotton Industry in China

Various factors contribute to the thriving cotton industry in China, with a major concentration in the bustling city of Shanghai.

- Favourable Climate: Shanghai is a port city with a humid climate. This humidity is crucial in the cotton industry as threads are less likely to break during production.

- Raw Material: The Yangtze-Kiang Delta, where Shanghai is located, is fertile ground for cotton cultivation.

- Transport: Shanghai benefits from its status as a port city, offering easy access to international markets. Additionally, the city is well-connected by rail and road networks, facilitating the movement of raw materials and finished products.

- Water and Energy: The Yangtze River not only serves as a transportation route but also provides a source of water and energy. Access to water resources is crucial for textile industries. Furthermore, the river can be harnessed for hydroelectric power.

- Labour: With a large population, Shanghai has a pool of skilled workers who contribute to the manufacturing process.

- Market: Within 1000 nautical miles, major markets like Kobe, Taiwan, South Korea, and Hong Kong are accessible, facilitating international trade. Moreover, within China, cities like Nantong, Wuhan, and Chongqing, connected via the Yangtze River, create a robust domestic market.

Other centres in China include Hwang-Ho Valley, Sichuan, Nanjing, Beijing, etc.