Table of Contents

Sugar Industry in India

This article deals with the ‘Sugar Industry (in India and World).’ This is part of our series on ‘Geography’, which is an important pillar of the GS-1 syllabus. For more articles, you can click here.

Introduction

India is the world’s second-largest sugarcane producer, and sugarcane stands as its most crucial cash crop. In addition to yielding sugar, jaggery, and khandsari, it furnishes molasses for the alcoholic beverage sector and bagasse for the paper manufacturing industry.

Locational factors

1. Raw material

- The sucrose content in sugarcane starts to decrease as time passes after harvesting, making it imperative for the sugar to be extracted within 24 hours to achieve better recovery. As a result, the ideal location for sugar mills would be close to the sugarcane fields to minimize transportation time and maximize sucrose content preservation.

2. Weight loss

- The weight loss of sugarcane during processing is significant, with sugar accounting for around 10% of the total bulky sugarcane. This high weight loss further underscores the importance of situating sugar mills near the source of raw material, as it reduces transportation costs and logistical challenges associated with moving large quantities of sugarcane over long distances.

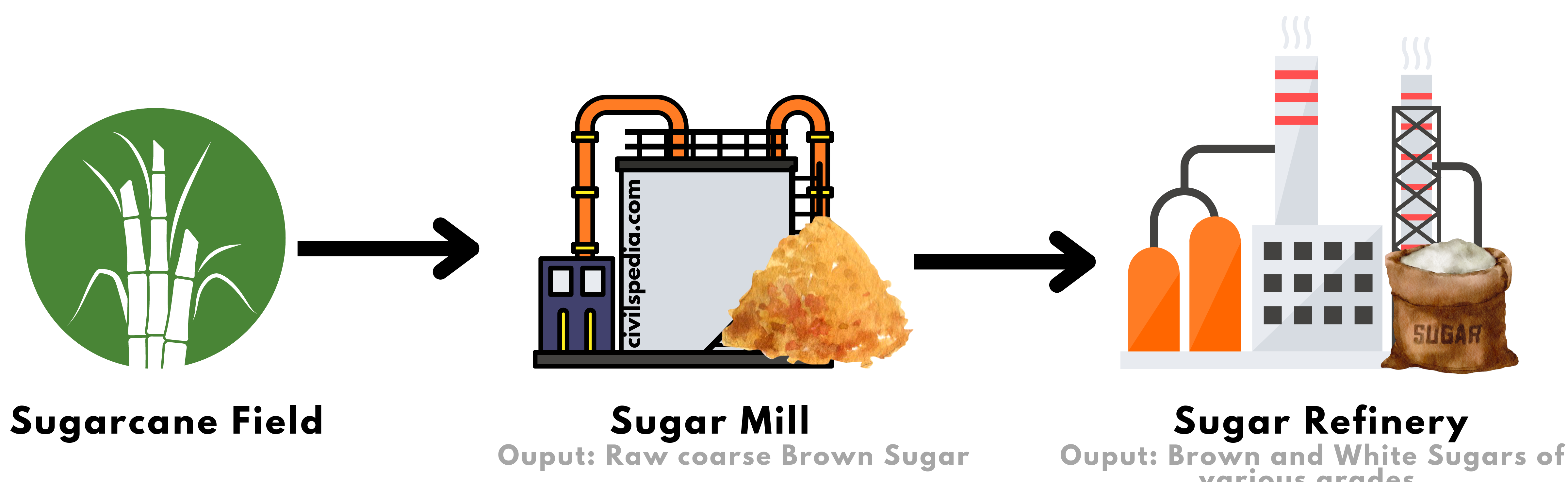

Sugar Mill & Sugar Refinery : 2 Separate Location Principles

Sugar Mill

The core unit of the Sugar Industry is the sugar mill, a facility where sugarcane undergoes a series of processes to yield various forms of sugar products.

| Input | Sugarcane |

| Process | Sugar juice + boiling =brown sugar |

| output | Raw Coarse Brown Sugar, Bagasse and Molasses |

| Location Principle | Regarding the location of sugar mills, they are strategically placed in close proximity to sugar-farming areas to minimize the transportation costs of raw sugarcane. This proximity ensures freshly harvested sugarcane can be quickly transported to the mill for processing, minimizing transportation time and maximizing sucrose content preservation. E.g. in Uttar Pradesh, Maharahstra, South Gujarat. |

Sugar Refinery

Sugar Refinery transforms the raw coarse brown sugar obtained from sugar mills into refined sugars of various grades, including brown and white sugars.

| Input | Raw Coarse Brown Sugar (from sugar mill) |

| Process | Raw Sugar is refined |

| output | Brown and White sugars of various grades. |

| Location Principle | Sugar refineries are strategically located near their target markets. By situating the refineries close to major urban centres or food processing industries, the sugar industry can effectively supply its products to various sectors of the economy, including food and beverage production, confectionery, and other consumer goods. |

Cuba is the Sugar Bowl of the world. WHY?

The following factors contribute to Cuba’s remarkable success in the sugar industry.

Climate

- Cuba’s high temperatures and the prevalence of the northeast trade winds create an ideal environment for sugarcane cultivation.

Soil

- The fertile calcareous soil in Cuba allows sugarcane crops to thrive and ensures that multiple harvests can be obtained within a year.

Capital

- The influx of American capital following the Spanish-American War in the late 19th century facilitated modernization, technological advancements, and increased efficiency in sugar production.

Market

- Cuba has a strategic geographic location due to its proximity to the United States and its relatively short distance from northwest Europe.

Labour

- Slave labour was used to cultivate sugarcane, resulting in significant production.

Government policy

- Before the rise of Fidel Castro, the main market for Cuba’s sugar exports was the United States.

- After the Cuban Revolution, the focus shifted towards other markets, such as the Soviet Union, and the country experimented with cooperative and collective models of sugar production.

USA is a major producer of sugar?

Sugar production is primarily concentrated in two distinct regions: Louisiana and Hawaii.

Louisiana

- Subtropical climate is conducive to sugarcane cultivation.

- Earlier, cheap labour was available. Later, they invested in automated harvesting machines and precision agriculture techniques.

Hawaii

- Hawaii’s islands’ volcanic soils are suitable for sugarcane cultivation.

- Historically, Hawaii’s sugar industry relied heavily on immigrant labour, including Japanese, Chinese, Filipino, and Portuguese workers. Later, they invested in Mechanized methods like combine harvesters and automated irrigation systems.

Other Producers: Mauritius and Fiji

Soil and Climate

- Soil is favourable for sugarcane cultivation

- Wet Climate favours sugarcane plantations.

Labour

- Indentured labourers played a crucial role in establishing and sustaining the sugar industry in these island nations.

Sugar Industry in India

- In India, the sugar industry holds significant prominence as it leads the world in the production of both sugarcane and cane sugar.

- Besides, khandasari and gur or jaggery are also prepared from sugarcane.

- This industry directly employs 4 lakh persons.

- Development of the industry on modern lines dates back to 1903 when a sugar mill was started in Bihar. Subsequently, sugar mills were started in other parts of Bihar and Uttar Pradesh. In 1950-51, 139 factories were in operation. The number of sugar factories rose to 662 in 2010-11.

Concentration of Sugar Mills in India

The sugar industry in India is geographically diverse, with various regions contributing significantly to its production.

Maharashtra

- Maharashtra stands out as the largest sugar producer, accounting for over one-third of the country’s total output.

- The sugar

industry in Maharashtra is concentrated in the following regions

- Western Maharashtra’s river valleys

- Sangli, Solapur and Satara

- Ahmadnagar, Pune and Nasik

Uttar Pradesh

- Uttar Pradesh is the second-largest sugar producer in India.

- The sugar

industry in Maharashtra is concentrated in the following regions

- Western UP and Terai region

- Meerut, Moradabad and Muzaffarnagar

- Sitapur, Gorakhpur and Saharanpur

Tamil Nadu

- Tamil Nadu’s presence in the sugar industry is notable, with Coimbatore and Tiruchirapalli as key centres of production.

Karnataka

- In Karnataka, Chitradurga and Shimoga are instrumental in contributing to the state’s sugar output.

Andhra Pradesh

- Andhra Pradesh’s sugar industry is prominent around cities like Hyderabad and Nizamabad.

Sugar Mills are concentrated in Maharashtra?

The concentration of sugar mills in Maharashtra, India, can be attributed to a combination of various favourable factors

- Favourable Climate

- The warm climate supports better yield, and Maharashtra benefits from the abundant sunlight and warmth.

- The proximity to the ocean further enhances the sugarcane growth, as the minimal temperature fluctuations between day and night increase sugar yield and sugar content within the cane.

- Soil: Lava soil in the region enhances fertility and water retention capabilities. This soil characteristic proves beneficial for sugarcane growth.

- Energy: Mills use bagasse as fuel ( and is not a deciding factor in the case of the Sugar industry)

- Transport: The transport infrastructure, specifically the presence of Mumbai Port, plays a crucial role in facilitating exports.

- Labour: The transport infrastructure, specifically the presence of Mumbai Port, plays a crucial role in facilitating exports.

Sugar Mills are concentrated in UP?

The sugar industry in India has a significant concentration of sugar mills in the state of Uttar Pradesh (UP). Various factors have influenced this geographical concentration.

- Soil Composition: The presence of potash and lime in the soil of Uttar Pradesh provides a favourable environment for sugarcane growth.

- Abundant Water Resources: The state of Uttar Pradesh is blessed with major rivers like the Ganga and Yamuna, along with their numerous tributaries.

- Energy Efficiency: Sugar mills in Uttar Pradesh have adopted an eco-friendly approach by utilizing bagasse, a by-product of sugarcane processing, as a renewable energy source.

- Well-Connected Transportation Network: The dense road network in Uttar Pradesh and its flat terrain facilitate easy sugarcane transportation from farms to mills.

- Seasonal and Migratory Labour: The availability of seasonal and migratory labour in Uttar Pradesh helps maintain lower production costs.

- Large Domestic Market: With its substantial population, Uttar Pradesh boasts a large domestic market that exhibits a consistent demand for various sugar products like gur, khandsari, and sugar itself.

- Government Intervention: Regulatory measures, subsidies, and price support mechanisms impact the industry’s economic dynamics and stability

Sugar Industry: North vs South

When comparing the sugar industries in North and South India, it’s intriguing to note that despite the favourable climatic conditions for sugarcane growth in the southern regions due to the absence of extreme heat, frost, and the moderating influence of the sea, the northern part of the country has a greater concentration of sugar industry. This phenomenon can be attributed to historical, economic, and agricultural factors.

- Historical Factors: During the British colonial period, the northern regions of India were known for cultivating indigo, a plant used for producing natural dyes. However, with the advent of synthetic dyes, the demand for natural indigo diminished, leading many farmers in the North to seek alternative crops. Sugarcane emerged as a viable substitute due to its potential for sugar production.

- Other Options Available: Despite the climatic advantages in the South, farmers in those regions have better options for cultivating cash crops. Cash crops like cotton, tobacco, and coconut are well-suited to the southern climate and soil conditions.

- In the North, the historical presence of sugar mills and the availability of infrastructure might have facilitated the growth of the sugar industry.

Problems Faced by the Sugar Industry in India

- Problem with State Advised Price (SAP): Due to political considerations, SAP is kept high, making sugarcane the most attractive crop to grow (due to this, it is grown even in drought-prone regions like Maharashtra). As a result, sugar mills are forced to pay high prices, culminating in high arrears to farmers.

- Low Yield of Sugarcane: Per hectare, sugarcane productivity is low in India compared to global standards. For instance, productivity in India is 64.5 tons/hectare compared to Java – 90 tons/hectare & Hawaii – 120 tons/hectare.

- Mismatch between Sugar and sugarcane prices: The government tries to keep sugar prices low (to get the votes of consumers) but sugarcane prices high (to get the votes of farmers). As a result, sugar mills suffer losses.

- Over-Regulation:

- The sugar industry is an over-regulated industry. Every sugar mill is allocated a command area, and the mill is bound to purchase sugarcane grown in that area. Sugarcane farmers can sell their sugarcane only in designated mills.

- State governments fix the quotas for different end uses of molasses and restrict their movement outside the state.

- Some states have even restricted the selling of power generated from bagasse outside the state.

- Old and obsolete machinery: Most of the machinery used in Indian mills, particularly in UP and Bihar, is old and obsolete, being 50-60 years old