Table of Contents

Copper Industry in India and World

This article deals with the ‘Copper Industry in India and World.’ This is part of our series on ‘Geography’, which is an important pillar of the GS-1 syllabus. For more articles, you can click here.

Introduction

- Copper is essential for the electric industry.

- Due to the increase in demand, new mining & smelting techniques have developed.

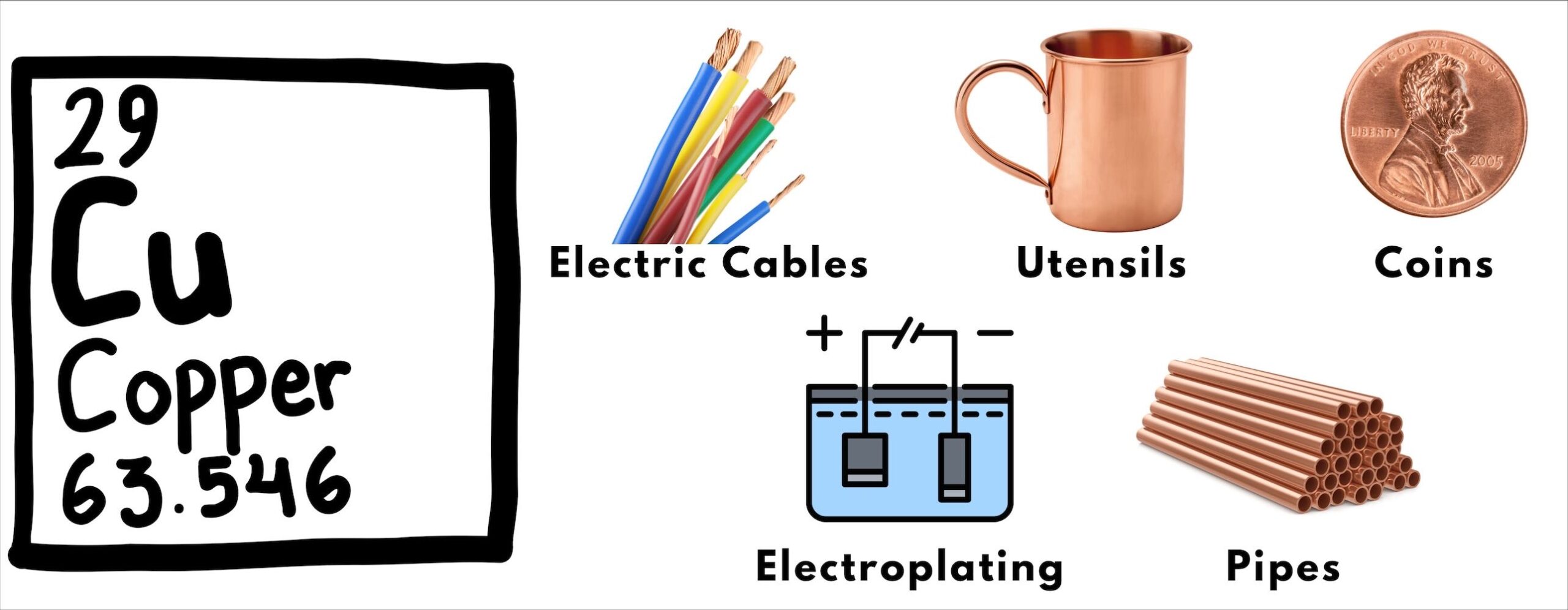

Uses of Copper

Stages of Copper Refining

- First stage, i.e. Concentration: In this process, we get blister copper using the froth floatation method, which is 2.5% of the original quantity. Hence, concentration is done near the mine.

- Second Stage: Blister Copper is 99% pure but can’t be used as such. Refining of Blister Copper is done using electrolysis. In this process, weight loss is just 1%. Hence, electricity is the deciding factor in this stage.

Location Factors of Copper Industry

- Availability of Copper Deposits: Regions with abundant copper ore reserves have a competitive advantage. For example,

- Malanjkhand copper deposit in Madhya Pradesh is one of India’s largest copper deposits, leading to the establishment of the Malanjkhand Copper Project.

- Khetri Copper Complex in Rajasthan is strategically located near the Khetri mines, a major copper ore source.

- Power Supply: Reliable and affordable power supply is essential for copper smelting and refining processes. Areas with access to sufficient electricity, preferably with a stable grid, are preferred.

- Infrastructure and Transportation: Adequate infrastructure, including transportation networks, is crucial for the copper industry. The Tuticorin Port in Tamil Nadu is an important hub for copper imports and exports, providing a favourable location for copper-related industries in the region.

- Skilled Labor Force: A skilled labour force with expertise in mining, metallurgy, engineering, and related fields is crucial for the copper industry.

- Government Policies and Incentives: Favorable government policies, like tax incentives, subsidies etc., can attract copper industries to specific locations.

- Market Access: Proximity to domestic and international markets is important for copper industries.

Global Copper Industry

1. Chile

- Chile is the world’s largest copper producer, accounting for a significant portion of the global copper supply. The country’s vast copper deposits are mainly located in the Atacama Desert.

2. Zaire and Zambia

- Zaire and Zambia, both African nations, possessed significant copper ore reserves and established refineries to process the raw material into valuable copper products. In an effort to exert more control over their natural resources and economic sectors, the governments of Zaire and Zambia chose to nationalize these refineries.

- However, the nationalization of the copper refineries did not go as planned, and the refineries began to face financial struggles, turning into loss-making ventures due to mismanagement, lack of expertise, and changing market dynamics.

3. China

- China is a significant player in both copper production and consumption. Major copper-producing provinces in China include Jiangxi, Inner Mongolia, and Xinjiang.

4. Australia

- Australia has substantial copper resources and availability of cheap electricity.

5. Indonesia

- Indonesia is a major copper producer, with its Grasberg mine being one of the world’s largest copper and gold mines.

6. USA

- The Copper industry was concentrated around the states of Utah, Montana, and Arizona (UMA). These states are known for their historical significance in copper mining and refining.

- However, the landscape of the industry in the UMA region started to shift due to factors such as rising costs of electricity, legal requirements to curb sulfur dioxide emissions necessitating expensive upgrades and Foreign competitors offering increased competition.

7. Canada

- Canada has copper production primarily in provinces such as British Columbia and Ontario.

8. Russia

- Russia’s copper operations are concentrated in regions like the Ural Mountains and Siberia.

9. Mexico

- Mexico’s copper production is centred in areas like Sonora and Zacatecas.

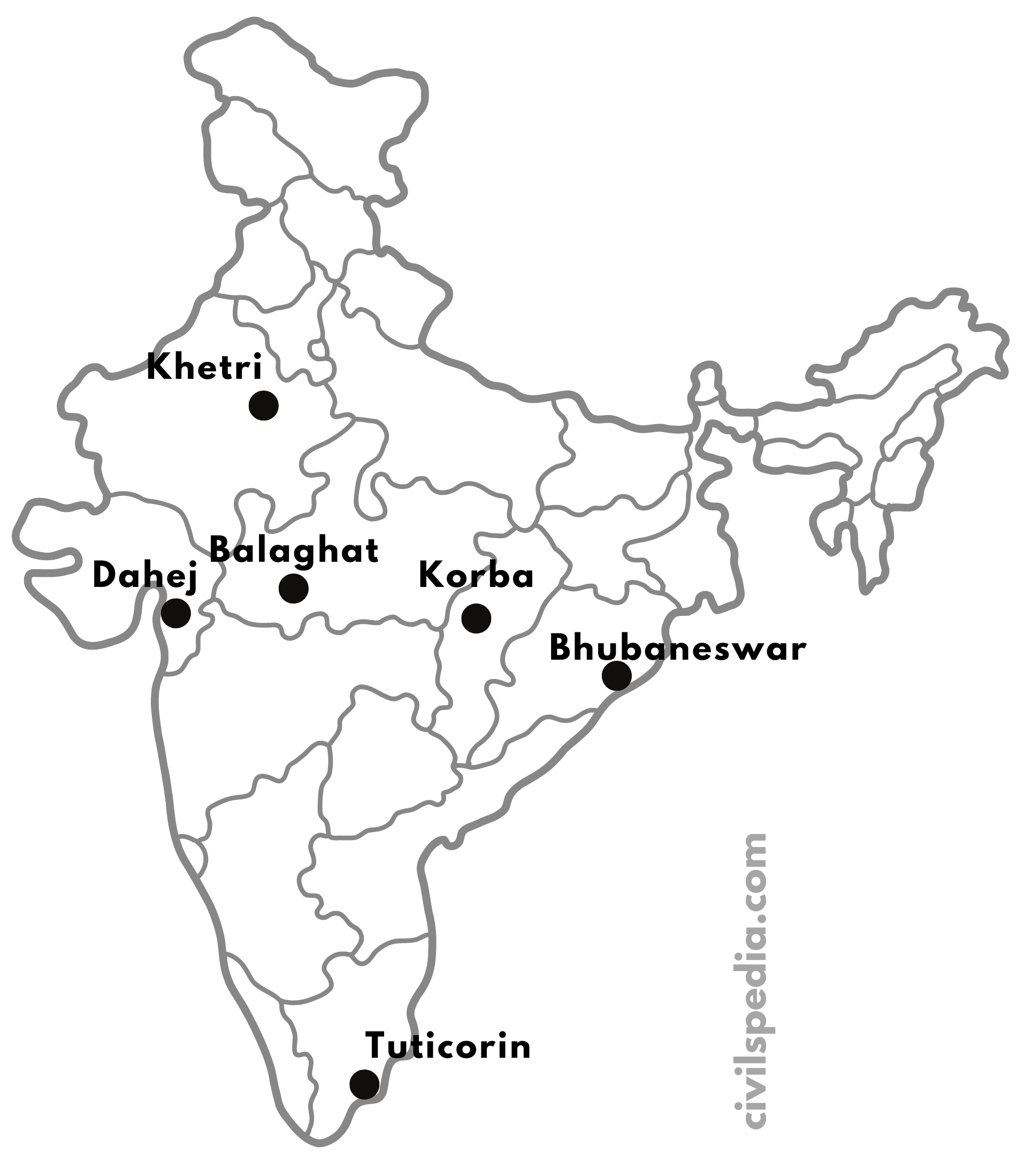

Main Copper producing units in India

1. Khetri, Rajasthan

- Khetri, in the Jhunjhunu district of Rajasthan, is one of India’s largest copper mining and smelting complexes.

- It is operated by Hindustan Copper Limited (HCL) and houses one of the oldest copper mines in the country.

2. Korba, Chattisgarh

- Korba unit is operated by BALCO.

- It gets its ore from Amarkantak and electricity from Korba thermal plant.

3. Dahej, Gujarat

- HINDALCO (a company of the Aditya Birla Group) has its Copper Division in Dahej (in Bharuch district of Gujarat).

4. Balaghat, Madhya Pradesh

- The Malanjkhand Copper Project, located in Balaghat, is one of the largest open-pit copper mines in India.

- It is operated by Hindustan Copper Limited.

5. Bhubaneswar, Odisha

- Bhubaneswar, the capital city of Odisha, is home to the Indian Copper Complex (ICC) smelter and refinery operated by Hindustan Copper Limited.

6. Tuticorin, Tamil Nadu

- Tuticorin in Tamil Nadu houses Sterlite Copper Smelter, which is one of the largest copper smelters in India.

- However, the smelter has been non-operational since 2018 due to environmental concerns.

dear sir

ab ceramics manufacture bricks ceramics band pipe lien cast bsalt band 80NB to336 383 NB all work cement copper power plant

thanks

dear sir

good