Aluminium Industry in India and World

This article deals with the ‘Aluminium Industry in India and World.’ This is part of our series on ‘Geography’, which is an important pillar of the GS-1 syllabus. For more articles, you can click here.

Introduction

Aluminium is abundant in the earth’s crust, but a significant concentration in one place is needed for mining.

Useful Properties of Aluminium

The following properties of Aluminium make it a valuable metal.

- Elasticity: Aluminium exhibits impressive elasticity, allowing it to be bent and deformed without easily breaking. This property is vital in applications where materials must withstand varying stresses and strains.

- Conductivity of Electricity and Heat: Aluminium boasts excellent electrical conductivity, allowing it to transmit electric current efficiently. Hence, it is preferred for heat sinks, radiators, and cookware.

- Modulability: Aluminium can be easily modulated into a wide range of shapes.

- Corrosion Resistance: Upon exposure to air, Aluminium forms a thin oxide layer that protects it from further oxidation, extending its lifespan and reducing maintenance requirements.

- Recyclability: Aluminium’s recyclability is noteworthy, as it can be recycled repeatedly without losing its fundamental properties.

- Lightweight: The low density of Aluminium contributes to its lightweight nature, making it an ideal choice for applications where weight reduction is crucial, such as in the aerospace and automotive industries.

- Non-Toxicity: Aluminium is considered safe for various applications due to its non-toxic nature, making it suitable for contact with food and beverages. This characteristic has led to its prevalent use in food packaging and kitchen utensils.

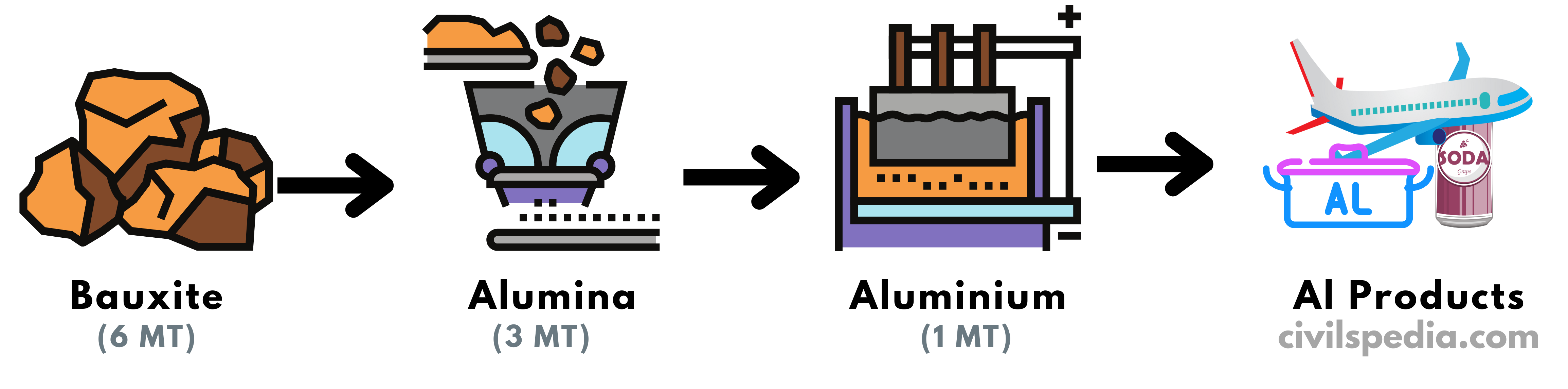

Process of obtaining Aluminium

Location Factors Influencing Aluminium Industry

Manufacturing one metric ton of Aluminium requires around 6 metric tonnes of Bauxite and power consumption of 18,573 kilowatt-hours of electricity.

- Bauxite Availability: The availability of Bauxite, the primary raw material for producing Aluminium, plays a crucial role in determining the location of Aluminium industries. Countries like Guinea, Australia, and Brazil, which possess significant bauxite reserves, enjoy a competitive edge in Aluminium production. They can obtain Bauxite at a lower cost compared to countries that need to import it, giving them an advantage in the Aluminium manufacturing sector.

- Cheap Electricity: Alumina to Aluminium conversion is done using electrolysis. Aluminium smelters require large amounts of energy, often supplied by hydroelectric power plants near the smelter. Therefore, Aluminium plants are usually located near water sources and dams that can generate electricity.

Global Aluminium Industry

The availability of cheap electricity has influenced the location of the Aluminium industry. This factor has played a significant role in determining the locations of main Aluminium refining centres worldwide.

During the 1970s, countries like Japan, the USA, and Western Europe were prominent players in the Aluminium industry. However, as the cost of electricity increased in these areas, they faced challenges in maintaining their competitive edge. This shift in competitiveness prompted the relocation of Aluminium production facilities to other regions that offered more cost-effective electricity options.

Presently, major Aluminium refining countries include Australia, Canada, Brazil, China, and Russia. These countries have been able to maintain their competitiveness due to their relatively low electricity costs.

Main Producers Include

1. Canada and Norway

- Canada and Norway are prime examples of countries that lack domestic bauxite resources but have a strong Aluminium industry presence.

- The availability of cheap electricity, primarily from hydroelectric resources, has enabled these nations to attract Aluminium refining companies.

2. Japan

- Japan, once a leader in Aluminium production, faced a decline due to rising electricity prices. Consequently, many companies shifted their operations to countries like Australia and Indonesia, which offer abundant bauxite reserves and comparatively lower electricity costs.

3. Australia

Australia stands out due to its significant deposits of bauxite and diverse electricity generation sources.

- Queensland & Victoria: In regions like Queensland and Victoria, coal-based thermal power plants contribute to the availability of cheap electricity

- Tasmania: Tasmania benefits from its ample hydroelectric resources.

4. USA

The United States, with its vast geography, has seen Aluminium production centres in various regions.

- Eastern USA: The eastern part of the USA, encompassing states like Arkansas, Georgia, and Alabama, has historically been associated with Aluminium production.

- Western USA: Western states like Arizona, Utah, and New Mexico have also hosted Aluminium refineries.

However, environmental considerations and taxes have impacted the growth of the Aluminium industry in the USA.

5. Iceland

- Iceland has emerged as an attractive destination for Aluminium companies due to its abundant supply of low-cost and renewable energy sources. The country’s geothermal and hydroelectric energy has lured Aluminium manufacturers seeking energy-efficient and sustainable operations.

Main Aluminium producing units in India

The Aluminium smelting sector holds the second most significant position in India’s metallurgical landscape, trailing only behind the iron and steel industry. Its contribution is pivotal to the comprehensive growth of the nation’s industrial sector.

Aluminium Industry in India

Both private and public sector enterprises are present in Aluminium production

1. Private Sector

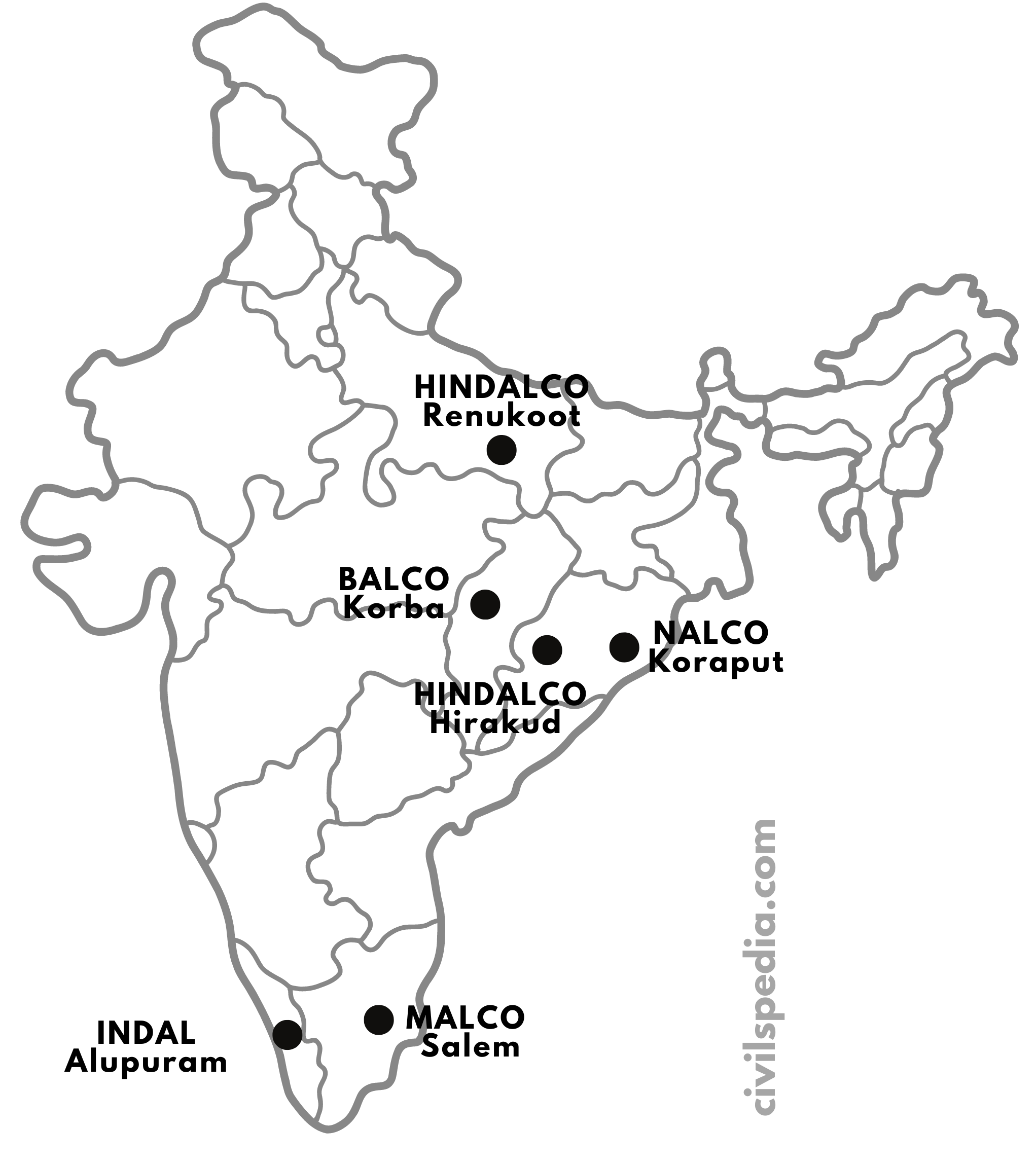

1. HINDALCO

HINDALCO, owned by the Aditya Birla Group, is a prominent player in the Indian Aluminium industry. The company operates two major plants in Renukoot (Uttar Pradesh) and Hirakud (Odisha).

a. Renukoot Plant, Uttar Pradesh (UP)

| Bauxite | Lohardaga-Pakhar region in Jharkhand |

| Electricity | Rihand Dam on the Rihand River |

| Skilled Labour | Comprehensive residential township and medical facilities are present to ensure a conducive working environment. |

| Transportation | Well connected via rail and road |

b. Hirakud Plant, Odisha

| Bauxite | Kalahandi-Koraput region in Odisha |

| Electricity | Captive coal blocks at Talabira |

| Transportation | Well connected via rail and road |

2. Public Sector Undertakings (PSUs)

1. National Aluminium Company (NALCO)

- NALCO is a leading PSU in the Indian aluminium industry, with its primary facility located in Koraput, Odisha.

- The company capitalizes on the abundant bauxite reserves in Odisha.

- NALCO’s operations are supported by a coal-based captive power plant, ensuring a steady energy supply for its Aluminium production processes.

2. Madras Aluminium Company (MALCO)

- MALCO is situated in Salem, Tamil Nadu.

- The Shevaroy Hills in Tamil Nadu provide the necessary Bauxite.

- The company utilizes hydroelectricity from the Mettur Dam to power its Aluminium production operations.

3. Bharat Aluminium Company (BALCO )

- BALCO, located in Korba, Chhattisgarh.

- The Korba region is rich in Aluminium reserves.

- BALCO relies on a coal-based captive power plant for its energy needs.

4. Others

- Indian Aluminium Company (INDAL): In Alupuram, Kerala